Rugged flexible screw is

the only moving part

contacting material,

moving free-and non-free-flowing materials that tend to pack, cake or smear, with no separation of blended products. It is driven above the point at which material is discharged, preventing material contact with bearings or seals. Small to wide diameter screws in many geometries handle low to ultra-high capacities.

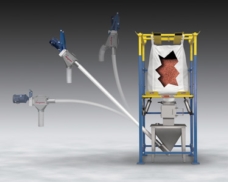

FLEXICON® Flexible Screw Conveyors

Move Virtually Any Bulk Material

Free-flowing and non-free-flowing materials and blends

Flexicon flexible screw conveyors (also known as helix conveyors, screw conveyors, spiral conveyors and auger conveyors) offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders—both free-flowing and non-free-flowing—with no separation of blended products.

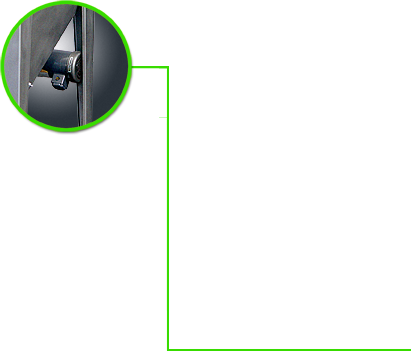

Material discharges from flexible screw conveyor below point at which it is driven, preventing material contact with seals.

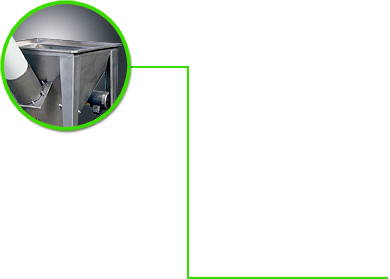

HIGH-FLOW HOPPERS

A wide range of standard and high-flow hoppers is available to feed the flexible screw conveyor's charging adapter.

CONVEYOR SCREWS

Flexible plastic, rigid plastic or rigid carbon/

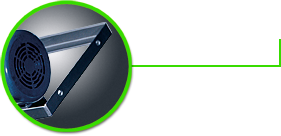

PROMOTION DEVICES

A variety of vibratory (shown) and mechanical hopper flow promotion devices is available to move non-free-flowing material into conveyor charging adapter.

Low horsepower motors, simple gear reducers and ultra-efficient operation significantly cut energy cost per volume of material conveyed.

DISCHARGE ASSEMBLY

The flexible screw conveyor discharge end can be suspended on chain or cable, attached to a ceiling support, or affixed to process equipment or the rim of a vessel.

Mobile and custom configurations

All Flexicon flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility, reducing the need for multiple stationary units.

Both mobile and stationary units are readily customized using interchangeable screws, conveyor tubes, drive motors, hoppers, flow-promotion devices, sensors, controllers, and other components to satisfy the most diverse and demanding end-use requirements.

Typical routing of flexible screw conveyors.

materials

materials

particles

dissimilar ingredients

materials

products

materials

materials

products

fluidize or liquefy

cake, smear, or plug